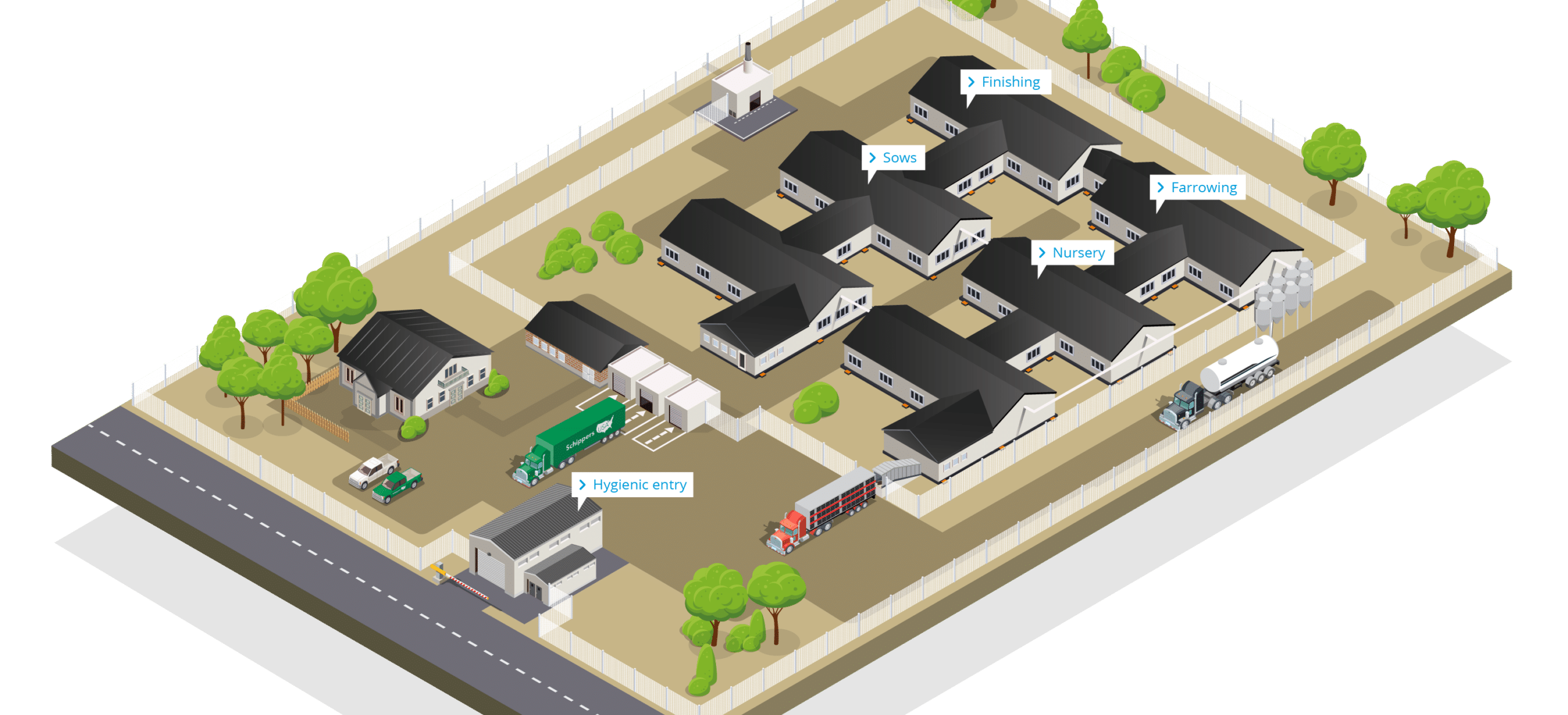

Sows

Improve the success rate of sow insemination, create a healty environment in the pregnancy area to maximize sow health and preventing cross-contamination before the transfer to the farrowing pen.

Finishing

The finishing phase is financially the most important. The herd consumes the most feed in this phase and animals stay in it for the longest period. Optimization and disease control significantly influence overall growth. Swine farm profitability and their efficiency highly depend on the performance in this phase.

Farrowing

Reducing pathogen pressure on newborn piglets in the early stages of their life significantly improves their performance during their entire life-cycle.

Nursery

Animals never get over a bad start, so it is critical to provide weaning piglets with healthy drinking water and an ideal germ-free growing environment to reach their full genetic potential.

Hygienic entry

External biosecurity measures are aimed at keeping the pathogens outside the farm.

Biosecurity programsfor pig farms

Farrowing

What’s important during this life stage?

Important at this phase is to minimizing pathogen pressure on piglets and prevent immune responses that hinder their growth. By prioritizing hygiene during this period, farmers reduce the risk of infections, improve piglet survival and growth rates, and ultimately ensure the long-term productivity and profitability of their operations.

Proper management practices include providing a clean and warm environment, ensuring adequate colostrum intake, minimizing the risk of crushing, and implementing disease prevention measures. Regular monitoring by trained personnel and veterinary care can help identify and address risks promptly.

Common challenges

- Historical Pollution: neglected washing or using low quality detergents can cause a layer of static pollution (1% that was not cleaned) to remain, a build-up of multiple layers of static pollution is called historical pollution which is a hospitable environment for pathogens.

- Navel infections: The umbilical cord of piglets can become contaminated during farrowing, leading to navel infections.

- Diarrhea: Commonly caused by pathogens such as E. coli, Clostridium perfringens, rotavirus, and coccidia. Leading to dehydration, electrolyte imbalances, and increased mortality.

- Hypothermia: Newborn piglets have limited ability to regulate their body temperature and are susceptible to hypothermia. Leading to decreased vitality and increased mortality.

Our HyCare biosecurity programs for farrowing

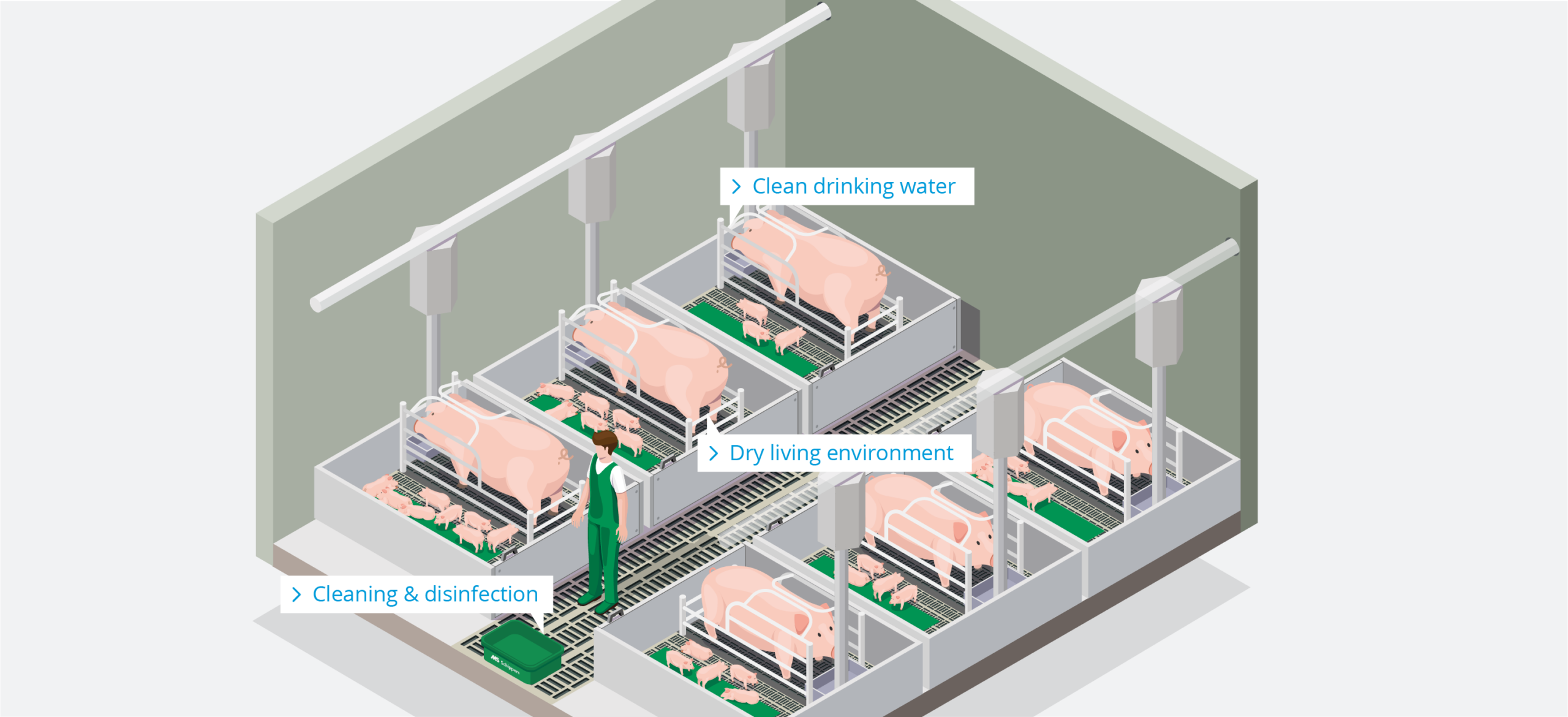

Cleaning & disinfection

The farrowing pen is thoroughly cleaned, disinfected, and prepared before the sows arrive. A germ free environment helps prevent cross contamination between different rounds.

Dry living environment

In the farrowing department we differentiate 3 main purposes for the use of hygiene powders:

- Preparation before farrowing

- Drying newborn piglets

- Environment control during the round

Clean Drinking Water

Animals need continuous access to a sufficient supply of clean and healthy drinking water to optimize their water intake and prevent pressure on their immune system from low quality water. To ensure the water quality remains, the water needs to be transport from the source to the animals through clean pipelines.

The HyCare clean drinking water program ensures the availability of healthy drinking water at all times.

The farrowing pen is thoroughly cleaned, disinfected, and prepared before the sows arrive. A germ free environment helps prevent cross contamination between different rounds.

In the farrowing department we differentiate 3 main purposes for the use of hygiene powders:

- Preparation before farrowing

- Drying newborn piglets

- Environment control during the round

Animals need continuous access to a sufficient supply of clean and healthy drinking water to optimize their water intake and prevent pressure on their immune system from low quality water. To ensure the water quality remains, the water needs to be transport from the source to the animals through clean pipelines.

The HyCare clean drinking water program ensures the availability of healthy drinking water at all times.

Contact our swine specialist

Carlos Zepeda

Carlos Zepeda is the Technical Biosecurity Specialist Swine for Schippers USA