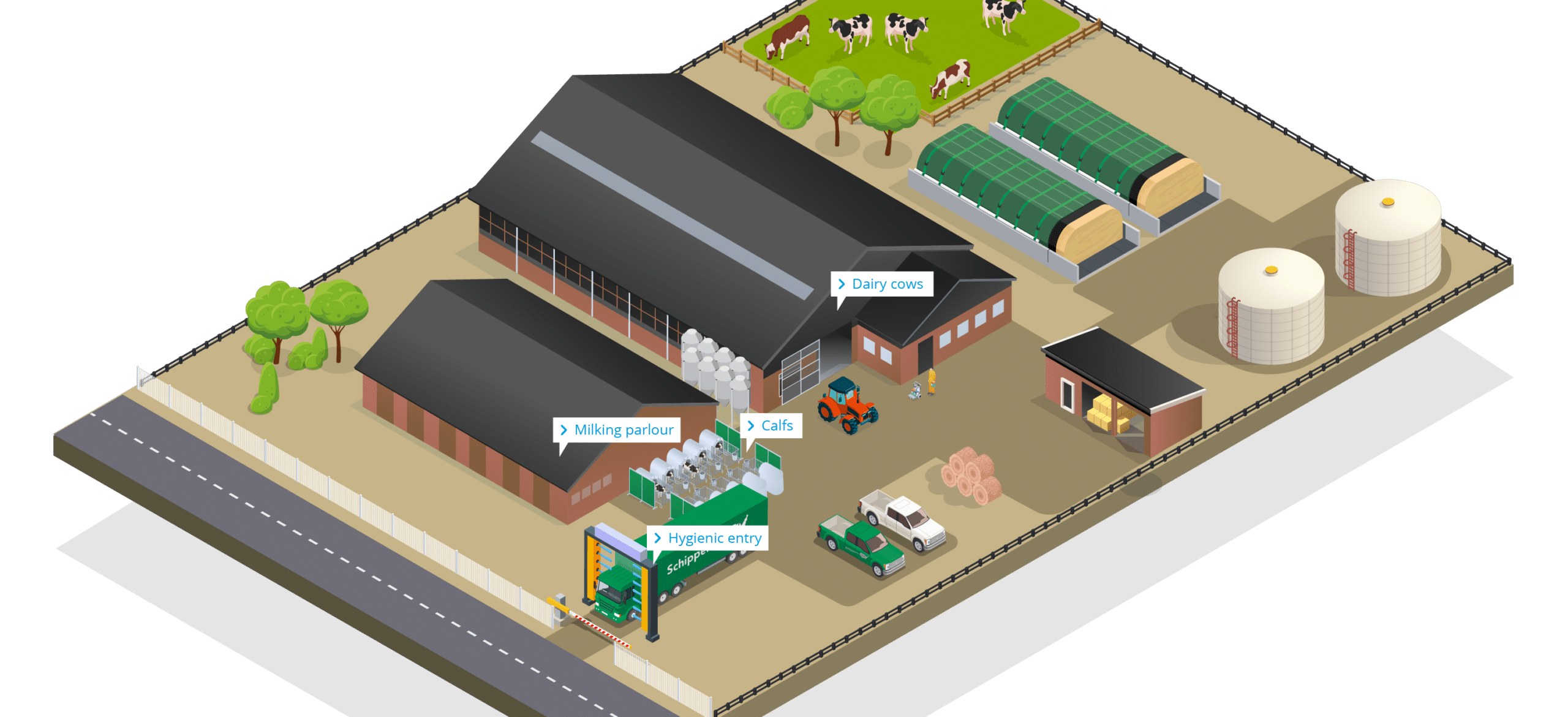

Dairy cows

These are the main shelters for dairy cows. Depending on the farm's setup, cows might be kept in freestall barns (individual stalls with bedding), tie-stall barns (cows are tied in individual stalls), or pasture-based systems. These barns provide protection from harsh weather conditions and also offer a controlled environment for managing the cows' health and comfort.

Milking parlour

This is where the milking of cows takes place. Milking parlors can vary in design, with options like herringbone, parallel, or rotary parlors. Modern milking parlors often use automated milking machines that milk multiple cows simultaneously, ensuring efficiency and reducing labor.

Calfs

The calf rearing area. Young calves are typically kept separate from adult cows to ensure proper care and growth. Calf rearing facilities have individual pens or group housing systems and provide the necessary nutrition, warmth, and attention to help calves develop into healthy replacements for the milking herd.

Hygienic entry

Many farms that focus on biosecurity include a hygienic farm entry area, usually a disinfection gate or manual cleaning and disinfection are for trucks, goods or persons that enter the farm.

Biosecurity programsfor dairy farms

Milking parlour

What’s important to maintain biosecurity at the milking parlour?

Maintaining biosecurity at the milking parlour involves implementing a set of practices and protocols to prevent the introduction and spread of diseases.

- Restricted Access: Limit access to the milking parlour to essential personnel. This reduces the risk of outsiders bringing in potential pathogens.

- Clean Environment: Keep the milking area clean and free from dirt, manure, and debris to minimize the presence of disease.

- Separation of Sick Animals: Immediately identify and isolate cows showing signs of illness, to prevent the spread of diseases during milking.

- Footbaths and Entry/Exit Points: To prevent the transmission of pathogens via footwear.

- Hoof Mats at exit: Taking care of the hoofs is important to ensure the health and longevity of your cows.

- Biosecurity Training: Educate milking staff about the importance of biosecurity.

- Monitoring: Maintain records of animal health, treatments, and any unusual incidents. This helps track disease history and assists in identifying the animals that need special care.

Common challenges:

- Mastitis: Leads to decreased milk quality and quantity, as well as discomfort for the cow.

- Lameness: Caused by poor hoof health, inadequate flooring, and improper nutrition. Impacts milk production, reproductive performance, and cow welfare.

- Stress and Behavior Issues: Caused by overcrowding, changes in routine, and poor handling during milking practices.

- Metabolic Disorders: Conditions like ketosis, milk fever (hypocalcemia), and displaced abomasum can occur due to imbalances in a cow’s metabolism around calving.

HyCare biosecurity programs programs for the milking parlour

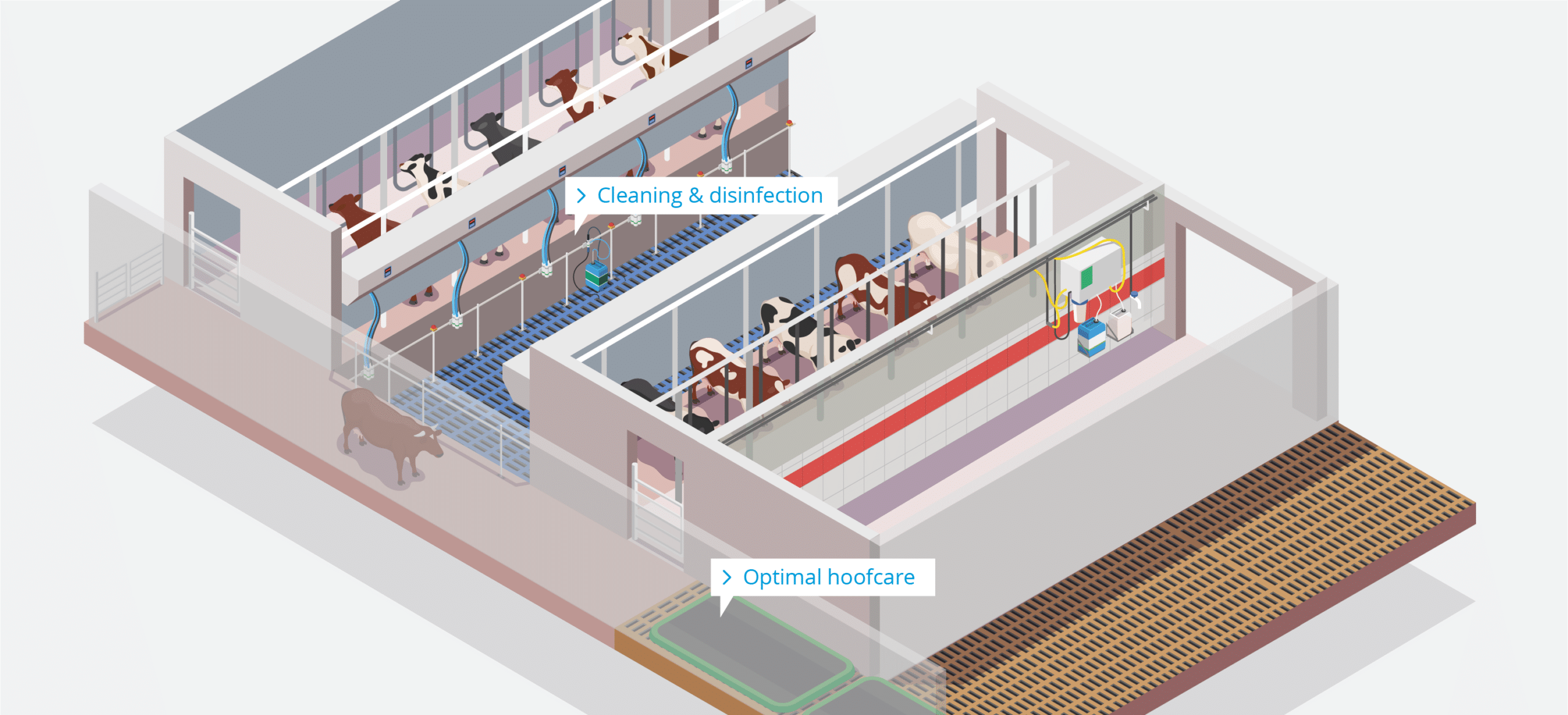

Optimal hoofcare

Healthy hooves are the foundation for proper water and feed intake in the dairy herd. Claw problems are a major negative influence on cow longevity. A lame cow often gets into a negative energy balance, which lowers her water and feed intake. This can also lead to fertility problems, which is another cause of premature dairy cow deaths.

The MS AutoHoofClean system is a fully automated system that is placed at the exit of the milking robot or in the return alley of a convential barn.

Two types of packages:

- Robot package: 6 feet mattress, 10 MS HoofClean jugs (5 gall) and a pumpunit.

- Convential package: 10 feet mattress, MS HoofClean jugs (depends on the amount of cows) and a pumpunit.

The pump unit is fully programmed so it knows when to fill the mat with MS HoofClean or a disinfectant. The mattress has a hard top layer with small holes so the chemical comes only out where the hoof will touch the mattress.

MS AutoHoofClean is a preventive and curative system against heel warts (digital dermatitis).

Cleaning & disinfection

The HyCare cleaning and disinfection program for the milking parlour focuses on creating a germ-free environment at the parlour. It is crucial for maintaining the health and well-being of dairy cows, producing high-quality and safe milk, preventing the spread of diseases, and complying with industry regulations. It’s an integral part of responsible dairy farming practices.

Healthy hooves are the foundation for proper water and feed intake in the dairy herd. Claw problems are a major negative influence on cow longevity. A lame cow often gets into a negative energy balance, which lowers her water and feed intake. This can also lead to fertility problems, which is another cause of premature dairy cow deaths.

The MS AutoHoofClean system is a fully automated system that is placed at the exit of the milking robot or in the return alley of a convential barn.

Two types of packages:

- Robot package: 6 feet mattress, 10 MS HoofClean jugs (5 gall) and a pumpunit.

- Convential package: 10 feet mattress, MS HoofClean jugs (depends on the amount of cows) and a pumpunit.

The pump unit is fully programmed so it knows when to fill the mat with MS HoofClean or a disinfectant. The mattress has a hard top layer with small holes so the chemical comes only out where the hoof will touch the mattress.

MS AutoHoofClean is a preventive and curative system against heel warts (digital dermatitis).

The HyCare cleaning and disinfection program for the milking parlour focuses on creating a germ-free environment at the parlour. It is crucial for maintaining the health and well-being of dairy cows, producing high-quality and safe milk, preventing the spread of diseases, and complying with industry regulations. It’s an integral part of responsible dairy farming practices.

Contact our dairy manager

Martijn Schippers

Martijn Schippers is the General Manager for Schippers USA and the manager for dairy and poultry.